Our Perforated Metal Infill Panels PDFs

Table of ContentsOur Perforated Metal Infill Panels DiariesPerforated Metal Infill Panels for BeginnersThe 2-Minute Rule for Perforated Metal Infill Panels

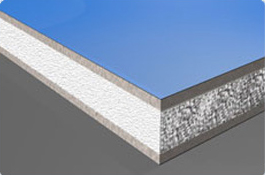

This is usually important in repair applications where the top quality of the initial flooring building and construction is not enough to stand up to hefty loads. Light steel outside wall surfacessupport light-weight cladding by dealing with directly via the insulation to the sustaining C areas or indirectly to horizontal rails that are taken care of to the C sections. Masonry cladding (brickwork )is relatively heavy and need to be ground-supported for wall surfaces as much as 12m high - perforated metal infill panels. For taller wall surfaces, it ought to

be sustained by the key structure making use of stainless steel angles linked to the edge light beams. It is tied back to the infill wall surfaces utilizing vertical networks in which the wall surface ties are located. In medical facilities, schools as well as various other similar applications, light steel infill wall surfaces and also separating walls have essential benefits by being re-locatable as need for space modifications during the life of the structure. Steel is non-combustible unlike wood

The Facts About Perforated Metal Infill Panels Revealed

as well as fire resistance periods of up to 120 minutes can be accomplished making use of numerous layers of' fire immune' plasterboard - perforated metal infill panels.

ideally not include more than 20 %to the total warmth loss with the building envelope.

The Best Guide To Perforated Metal Infill Panels

Actual air infiltration rates under typical problems are only around 5% of the test worth, depending on the dimension of the buildingand also its usage. For verysecured structures, such as laboratories, fresh air top quality must be preserved by suitable air try this website flow of cleansed air. Condensation is a sensation where cozy damp air condenses on chilly surface areas. This result is minimised by guaranteeing that chilly spots on the inner surface area of the structure are within limitations( usually 10 % of the temperature level of theremainder of the wall surface). Where there is a danger of condensation within the cladding itself, a vapour tight membrane layer might be positioned on the within the structure. by utilizing audio insulating boards rather common wall surface board or by increasing the variety of layers. For outside wall surfaces as well as compartment wall surfaces, Authorized Paper B (England) mentions that the appropriate duration of fire resistance relies on the use, height as well as dimension of the structure. Where there is a threat that failing of the outside wall could cause fire infect adjacent buildings( a border problem ), the wall needs to satisfy fire resistance demands; this may influence the kind of cladding that can be made use of. In such instance, a brickwork external fallen leave that is laterally supported by the light steel infill wall surface may be liked. Materials accomplishing minimal combustibility can not be regarded to fulfill the need using an alternate classification technique. Amended regulation 7( 3 )gives an exception for sure parts found in exterior walls and specified accessories. Interpretations of outside wall surfaces and defined add-ons have been included as well as these interpretations consist of any type of components of the Look At This external wall surface in addition to certain accessories to the exterior wall (porches, solar panels and also sunlight shading ). An Appointment document was created on the suggested amendments to the Building Laws and the modifications to Part B exist in a file qualified' Modifications to the Accepted Records', December 2018 The major ramification for advice on infill walls for structures of even more than 6 floors is that insulation systems that do not please the above demand are not allowed - perforated metal infill panels. @&&h3@ [leading] Weather condition resistance @&&/h3@ 12 onwards in Authorized Document C. The exposure of exterior wall surfaces to wind driven rainfall is likewise depending on the geographical region that is identified as having' protected' to' very serious'exposure in conformity with BS 8104. Many parts of the UK autumn under the' moderate' or' severe' exposure zones. Table 4 of Approved Record C offers the minimum width of tooth cavity for the different direct exposure zones and also cladding materials. BS 5628-3 describes the elements impacting rain

infiltration in dental caries wall surfaces. For drape walling systems, the forms of building are defined in BS EN 13830. The Centre for Window and also Cladding Technology( CWCT) has actually also generated guidance on weather-tightness and connected major testing regimes for these light-weight built-up cladding systems, which might consist of some light steel supporting parts. Windows existing the highest possible risk of water infiltration as well as the following detail for insulated make programs just how to control water ingress. Assistance on the use and describing of insulated make cladding connected to light steel infill wall surfaces is given in SCI P343. The efficiency might be improved by utilize of proprietary window coverings which fit securely around the home window, as revealed listed below. Normal information of insulated cladding at a window Window company website shell information made use of with insulated render. @&&h3@ [top] Wind resistance @&&/h3@ @&&h2@ [